Advanced Site Characterization

UVOST

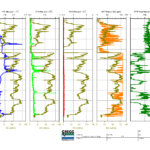

Gregg operates an Ultra-Violet Optical Screening Tool (UVOST) module that is located behind the standard

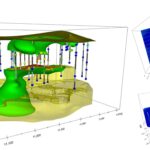

piezocone. The UVOST works on the principle that polycyclic aromatic hydrocarbons (PAH’s), located in soil and/or groundwater fluoresce when irradiated by ultra-violet light. Different types of PAHs will fluoresce at different wave lengths leaving a characteristic fluorescence signature. Measuring the intensity and wavelength of the fluoresced PAH allows one to assess the type and relative concentration of PAH present in the CPT-UVOST sounding. Performing CPT-UVOST soundings at multiple locations across a site allows for an accurate determination of the site stratigraphy and piezometric profile along with the location of the residual phase NAPL present at the site. These data can be used to select appropriate boring, sampling and monitoring well locations which allows for a more rapid, accurate and cost effective site assessment and remediation program when compared with the traditional multiphase drilling and sampling program.

HPT

The HPT system is designed to evaluate the hydraulic behavior of unconsolidated materials. As the probe is pushed or hammered at 2cm/s, clean water is injected through a screen on the side of the HPT probe at a flow rate usually less than 300 mL/min. The injection pressure, which is monitored and plotted with depth, is an indication of the hydraulic properties of the soil. A relatively low pressure response indicates a relatively large grain size, and the ability to easily transmit water. However, a relatively high pressure response indicates a relatively small grain size, which correlates with the inability to transmit water.

Additionally, an EC dipole is integrated into the HPT probe. This allows for the collection soil electrical conductivity (EC) data to interpret the lithology of the subsurface. In general, the higher the electrical conductivity value, the smaller the grain size, the lower the electrical conductivity value, the larger the grain size. However, other factors can affect EC, such as mineralogy and pore water chemistry (brines, extreme pH, contaminants). Conversely, the HPT pressure response is independent of these chemical and mineralogical factors.

There are five primary components of the HPT system: the probe assembly, controller, pump, trunk line, and field instrument. The probe assembly consists of the section that houses the 100psi pressure transducer, water and electrical connections, and the probe body with the injection screen and electrical conductivity.

Injecting water at a constant rate is integral to system operation. A controller box houses components that monitor and regulate the water injection rate and pressure, as well as pressure transducer signal conditioning electronics. The flow rate is set manually on the front of the controller, and a valve is used to turn on or shut off flow.

A vane pump provides system pressure ensuring adequate flow to the screen. The pump is secured to a frame with an integrated visual flow meter. Water and power are transmitted from the controller to the probe assembly via the trunk line. The probe rods are pre-strung with the trunk line before advancement of the HPT probe begins.

We’re ready for you

With over 35 years experience drilling in California and surrounding states, Gregg Drilling can handle any size project. We hope to demonstrate our value through quality equipment, knowledgeable and experienced personnel and our exceptional safety standards.